Read the Final Report and Executive Summary of Task 39 here: https://iea-es.org/publications/type/final-reports

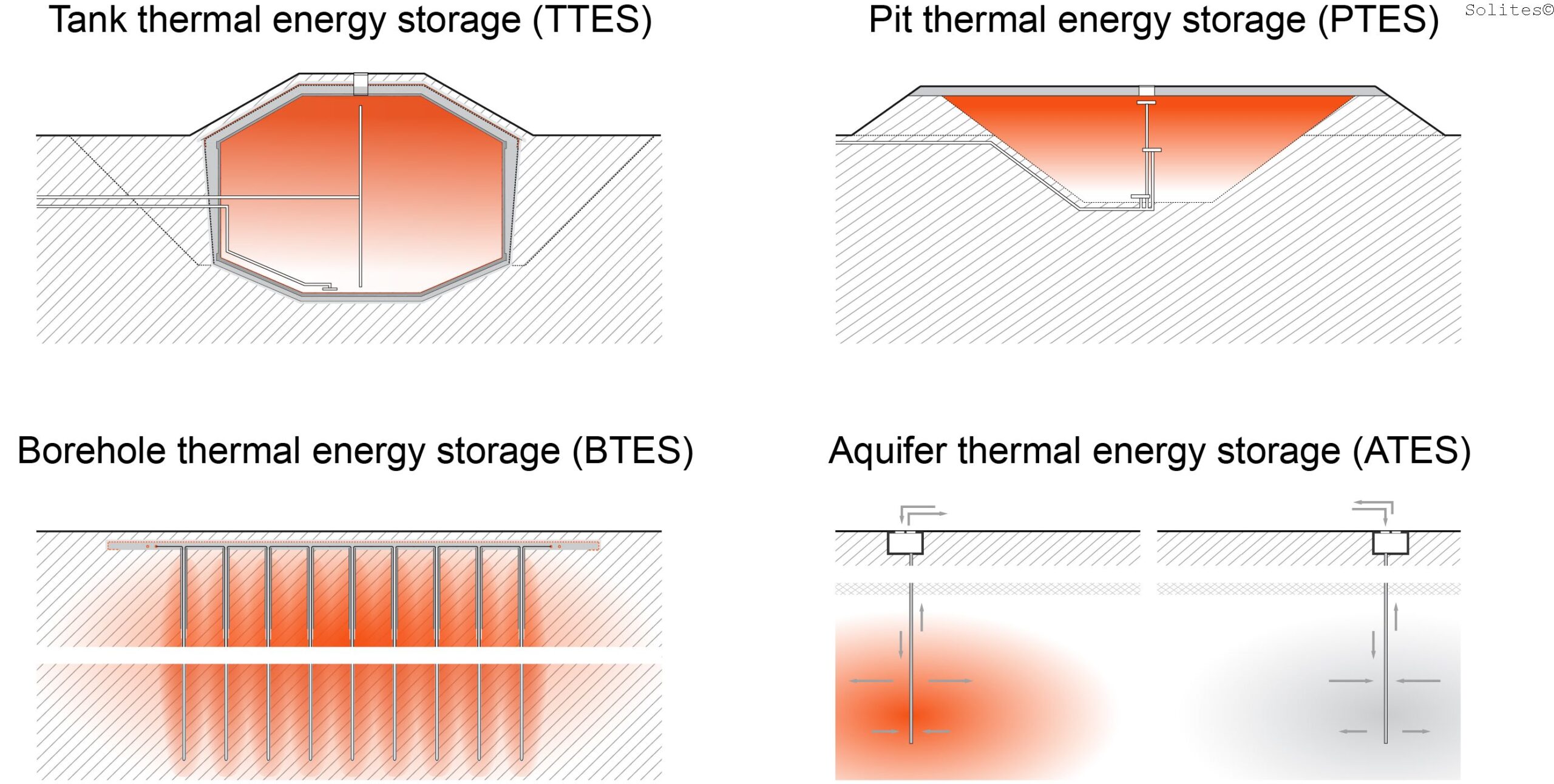

Different countries have ambitious goals for energy and climate change adaptation and mitigation, aiming for 50 % more efficient energy use and 100 % renewable energy generation. Thermal Energy Storage (TES) is a key enabling technology for a realisation of a carbon neutral energy system. District Heating (DH) is a mature technology for the heating of the built environment, especially in large cities. Large-scale Thermal Energy Storage (LTES) systems are necessary to further decarbonise the DH systems and to enable a more flexible operation. LTES are needed, in order to further reduce the specific costs of the storage technology and to have storage capacities that are better suited to the sizes of larger DH systems. Present experience with TES for integration in DH is in the utilisation of Pit Thermal Energy Storage (PTES) systems up to 200,000 m3 and of Tank Thermal Energy Storages (TTES) systems up to 50,000 m3. Also the subject of this task are the TES technologies Aquifer Thermal Energy Storages (ATES) and Borehole Thermal Energy Storages (BTES).

Motivation

Large-scale thermal energy storages offer more flexibility in DH Systems (also adding operational flexibility to power plants and industrial processes), they enable a higher share of renewables and waste heat, they can provide peak shaving functionality for electricity grids through Power-to-Heat (P2H) thus enabling sector coupling of the power and heating sector.

The market for large thermal energy storages is growing, with new plants built and planned in Denmark and Germany, mostly PTES with volumes in the range of 400,000 to 500,000 m³ (in Denmark). In order to facilitate and accelerate the market uptake of these large storages, better materials and knowledge is needed to improve the service lifetime of storages, better tools are needed for designing, planning and integrating the storages and more knowledge of the potential and integration possibilities of these storages is needed for decision makers.

Aim and Objectives of the Task

The Task aims at determining the aspects that are important in planning, design, decision-making and realising very large thermal energy storages for integration into district heating systems and for industrial processes, given the boundary conditions for different locations and different system configurations.

The key objectives of the Task are:

- Definition of a number of representative application scenarios, the connected boundary conditions and Key Performance Indicators

- Improve LTES materials and materials performance measurement methods

- Prepare guidelines for obtaining proper water quality

- Compare the performance and accuracy of simulation models for LTES

- Derive validation tests for LTES simulation models

- Generate information packages for decision makers and actively disseminate the information

For these purposes, four Subtasks work on the content subjects:

- Subtask A: Application Scenarios, Assessment of Concepts, Integration Aspects

- Subtask B: Components and Materials Database

- Subtask C: Round robin simulation

- Subtask D: Knowledge base for decision makers

Subtask Description and Main Outcomes

Subtask A: Application Scenarios, Assessment of Concepts, Integration Aspects

Subtask A was aimed at building a list of existing hot water seasonal storage in the world and select well documented and instrumented ones to be used as reference cases for Subtask C work. A second target consisted in defining a list of relevant technical and economical KPIs to assess and compare the different technologies considered (ATES, BTES, LTES, PTES). A last target consisted in building a matrix used as a support for decision makers to guide them in the first steps of a project definition to select suitable technology for their specific use.

The agreed definition of a Large Thermal Energy Storage in the scope of this Task is the following:

“LTES are sensible Thermal Energy Storages designed to store at least 1 GWh heat per year at atmospheric pressure. The stored heat should be suitable for discharge into District Heating Networks, at temperatures higher than 50 °C.”

Together with Subtask D, reference projects were described in leaflets, together with leaflets on the technology descriptions of aquifer-, borehole-, tank- and pit thermal energy storage.

A KPI list has been created and sets a first reference to assess the performances of those type of storage. It aims at being exhaustive regarding technical, economic and environmental aspects. The listed KPIs are introduced with their formula, unit, their use and a reference. Moreover, they are sorted in different categories:

- Their type: technical, economic or environmental.

- The storages they apply to: TTES, PTES, BTES and/or ATES.

- The scope of this KPI: storage alone, storage system or the whole DHN (see the figure below).

- The project stage when this KPI should be calculated: opportunity, design or operation.

- The main target group: policy makers, project owners/developers or researchers/engineers

Finally, a major part of the work in Subtask A was to provide guidelines for LTES project development to guide the different stakeholders in their understanding and role throughout an LTES project. First, a standard process development was introduced including the main activities, challenges and tools. Secondly, actual project developments were depicted parallel to the project development process, to give real-life examples on the activities and challenges introduced in the first part.

An additional activity was the creation of a list of existing LTES projects to gather all references in one spreadsheet and to provide a database for future project developers that would like to get a glimpse at previous experiences.

Subtask B: Components and Materials Database

The goal of Subtask B was to define common test procedures for hygrothermal and mechanical tests for materials, to define the water quality and to create a database for TES materials that go beyond the standard values.

The lifetime of the materials and components is crucial for the economic feasibility of all thermal storage technologies. Measuring the lifetime characterization of materials in real-time and scale is time-consuming. Generally, acceleration of measurement and minimizing the sample size are used. A test and assessment method based on miniaturized specimens was implemented at the Institute of Polymeric Materials and Testing by the University of Linz, AT. Special attention was given to the acceleration of the aging mechanisms by elevated temperature, and to specimen miniaturization.

As water used in most LTES system is equal or comparable to water used in district heating systems, the guidelines for water in DH can be used.

A status of available materials was gathered and listed. With the help of schematic drawings of each storage type, a principal visualization of their composition is intended. Initially, the gathered material and component data considered the PTES technology. A considerable choice of materials has been gathered, of which for nearly most materials a comment section has been filled to reveal closer information. The materials database will be hosted on the Supergen Energy Storage Network+ website, https://ukesto.supergenstorage.org, where UK energy storage facilities and databases are showcased.

Subtask C: Round robin simulation

The aim of Subtask C was to validate and compare numerical simulation models for LTES through Round Robin simulations. Models for aquifer (ATES), borehole (BTES), pit (PTES) and tank (TTES) storage concepts were considered. Different simulation tools were considered, either for system simulation or for TES design optimisation purposes. The table below gives an overview of the LTES simulation models used by Task39 partners.

| Purpose / Storage type | System simulation | TES design optimization | |

| ATES | TRNSYS: Type 345 TRNAST Type 1380 | FEFLOW MODFLOW HST2D/3D | |

| BTES | TRNSYS: Type 346 SBM , Type 370 Type 557 DST, Type 1373 | Modelica: MoSDH library – BTES model | COMSOL Multiphysics ANSYS FLUENT FEFLOW |

| PTES | TRNSYS: Type 343 (cone), Type 1322 (pyramid) Types 1535/1301 (cone), UGSTS MATLAB Simulink: Matlab Large-Scale TES | Modelica: Dymola Dis PlaTES LargeTESmtk – PTES model MoSDH library – PTES model | COMSOL Multiphysics ANSYS FLUENT OpenFOAM |

| TTES | TRNSYS: Type 340 (above ground) Type 342 (buried and above-ground) Types 534/708 (ground buried) Type 1534 (above ground) Types 1534/1302 (ground buried) | Modelica: Dymola Dis PlaTES LargeTESmtk – TTES model MoSDH library – TTES model MATLAB Simulink: Matlab Large-Scale TES | |

In total, 6 test cases for a first round of storage simulations were defined, with 28 institutions participating in the simulations, see the overview table below. In this first round, a very simplified annual charging/discharging profile was used. The comparison gave a very satisfying outcome, in detail described in the Subtask C deliverables.

| Test case | No. of participations | No. of participating institutions | No. of different LTES models |

| ATES-1 | 4 | 3 | 4 |

| BTES-1 | 6 | 4 | 4 |

| PTES-1-C | 12 | 9 | 6 |

| PTES-1-P | 2 | 2 | 2 |

| TTES-1-AG | 4 | 3 | 4 |

| TTES-1-UG | 9 | 7 | 7 |

Subtask D: Knowledge base for decision makers

The aim of this subtask was to gather information from the different subtasks to make a knowledge base for decision makers that might have to deal with the evaluation of projects including LTES. This information was disseminated to different target groups through a newsletter, various workshops, and the distribution of leaflets and other electronic information. The subtask’s goal was to create general interest in the target groups for implementing LTES and provide them with generic tools to identify the favourable conditions for it.

The main achievement of IEA-ES Task 39 is the reference information material on LTES to prepare the acceleration of LTES implementation for District Heating (DH) and industry. This material been developed by involving international experts of energy systems simulations, storage materials and storage constructions. Together, the experts have contributed to preparing state-of-the-art guidelines as well as a list of references for all key phases of an LTES project, from idea to realization. The developed information material is tailored for key stakeholders of LTES projects, especially policy makers, authorities, and utilities to broaden the general knowledge on the studied technologies. Task 39 has made the first thorough and accessible introduction of LTES technologies and associated tools for the relevant decision makers. The identification of the main stages of LTES project development has been an important outcome of Subtask A. These stages are used in the diagram below as a reference in the LTES project lifetime to show which main actor/target group is involved during which stage, and which information material from Task 39 is relevant for these stages. Each information material has an associated work package.

The information material is available on the Task 39 website as deliverables.